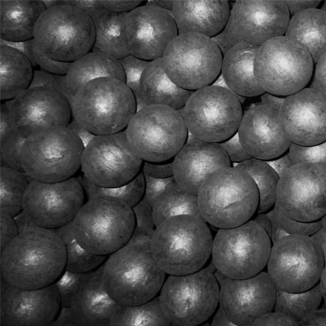

Forged Steel Balls for Cement Mill and Raw Mill Application

In the realm of cement and raw material milling, the significance of forged steel balls cannot be overstated. These balls, meticulously crafted through precision forging techniques, symbolize the epitome of durability and adaptability in grinding processes. Possessing exceptional strength, wear resistance, and impact toughness, they navigate the rigorous environments of milling with finesse. Beyond their robust composition ensuring extended service life, these forged steel balls elevate grinding efficiency, indispensable for achieving optimal cement quality and reducing particle size. As indispensable components in the milling process, they play a pivotal role in fine-tuning particle sizes, exemplifying their vital contribution to operational excellence within the dynamic landscape of the cement industry.

Casted Steel Balls for Cement Mill and Raw Mill Application

Casted steel balls emerge as vital components in the realms of cement and raw mill applications, showcasing their unique characteristics to enhance grinding processes. Precision-casted with meticulous attention, these steel balls bring durability and reliability to the milling arena. Their composition, carefully engineered for optimal performance, ensures effective reduction of particle sizes in the challenging environments of cement and raw material milling. Renowned for their wear resistance and consistent performance, casted steel balls contribute significantly to achieving fine particle sizes and maintaining high-quality output in these industrial processes. As indispensable elements in milling machinery, casted steel balls play a pivotal role in ensuring efficiency and excellence in the production of cement and raw materials, reflecting their crucial position in the landscape of material processing.